- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Mining Vibrating Screen>High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine

High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine

- Mining Vibrating Screen

Mining Vibrating Screen

- China

- CE ISO

- One set High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine

- [email protected]

- Standard

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 55

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine

Brief description - vibrating sizing sifter

XC series three-D vibrating sizing sifter is a special screening equipment with international level, high precision and fine particle on the basis of advanced technology from home and abroad. Its advantages are as follows: fully closed, no dust emission, continuous operation; high screening precision, efficiency and utilization rate of screen; small volume, light in weight, start quickly, low noise; easy operation, convenient maintenance, long service life of screen; the discharge port direction changed along the circumferential direction. The machine is widely used in screening fine powder, micro powder, submicron powder, bar, dry and wet materials.

Working principle - vibrating sizing sifter

Fundamental principles: rotary motion of the motor change into the horizontal, vertical, and inclined sports (three-D) through the installation of the ends of the weight (imbalance weight) on the vibration motor, and then transfer the motion to the surface of the screen. The trajectories of the material can be changed by changing the phase angle of the weight.

Details - vibrating sizing sifter

Characteristics - vibrating sizing sifter

1. The widest range of screening: applicable to all kinds of particles, powder, and slurry filter.

2. The mesh not block: a variety of specially designed screen of the cleaning device make the probability of blocking the mesh approach the minimum.

3. Single layer and multi-layer separation; Single layer filtration, once to achieve the requirements

4. Easy to change the screen; no deformation of the mesh, long service life of screen, high efficiency

Technical parameter - vibrating sizing sifter

Model |

Power (KW) |

Screen dish

|

Effective area (m²) |

layer

|

|

XC-600-1s XC-600-2s XC-600-3s |

0.25 0.55 0.55 |

560 |

0.2375 |

1 2 3 |

|

XC-800-1s XC-800-2s XC-800-3s |

0.55 0.75 0.75 |

760 |

0.4416 |

1 2 3 |

|

XC-1000-1s XC-1000-2s XC-1000-3s |

0.75 1.1 1.5 |

930 |

0.6789 |

1 2 3 |

|

XC-1200-1s XC-1200-2s XC-1200-3s |

1.1 1.5 1.75 |

1130 |

1.0382 |

1 2 3 |

|

XC-1500-1s XC-1500-2s XC-1500-3s |

1.5 2.2 2.2 |

1430 |

1.6052 |

1 2 3 |

Application - vibrating sizing sifter

The vibrating sizing sifter is widely used in chemical industry, food inductry, metallurgy, mine industry,medicinal industry, waste treatment and other industries, such as resin, starch, salt, copper powder, all kinds of medicine, disposed dye waste water etc.

About us

Certifications & honor

Our services

Before Sales:

Accept customer consultation, according to the customer demand; determine the scale of factory management, providing solutions.

For customer training technical personnel;

According to customer request, design and manufacture products;

Medium-sales:

Acceptance of the product;

Assist client protocol construction scheme;

After-sales:

On-site training personnel;

Appoint special after-sale service staff, arrived at the scene guide clients installation and commissioning;

Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication.

FAQ

1.How about the quality of your product?

a.Our products manufactured strictly according to national and international standard.

b. We take a test on every product before delivery.

Note: You had better send us the pictures you have ever used.

2.How about price of this product?

a. We can give the lowest price than market one.

b. We do quotation as soon as possible for any customer.

c. Discount can be given according to quantity.

Have any needs, just contact us !!!

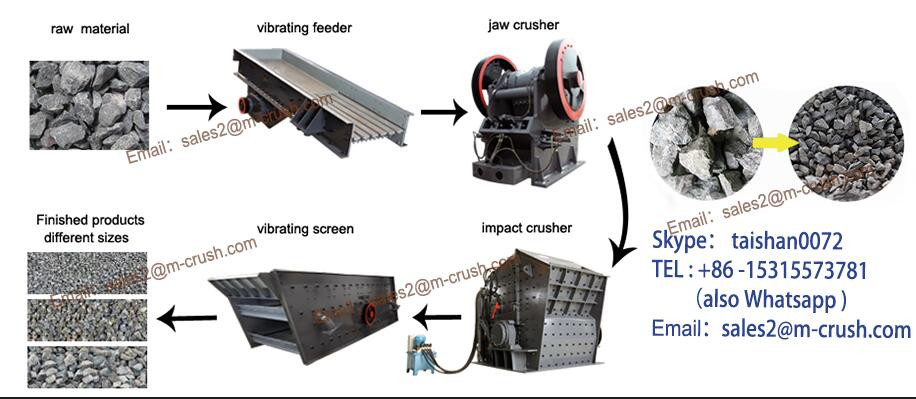

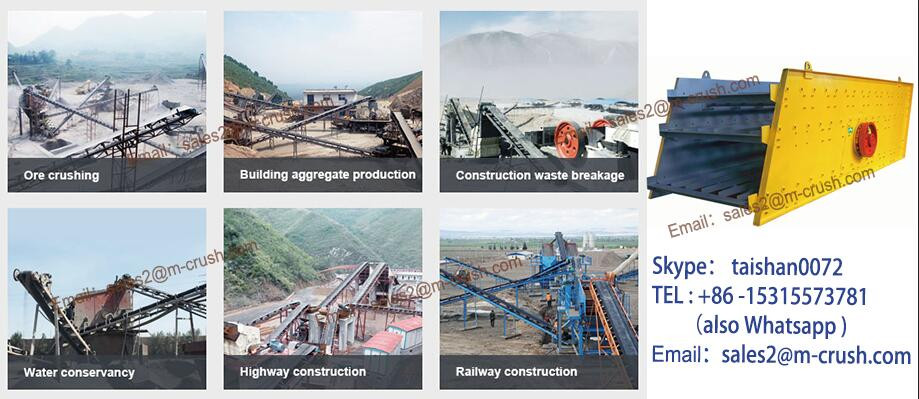

Mining Vibrating Screen is one of the unique product or equipment,High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

High Quality Precision Yeast Powder Vibrating Screen/ Sifter/ Sieve sizing machine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

2014 JXSC High Frequency mobile vibrating screen

2014 JXSC High Frequency mobile vibrating screen VD Vibrating Drainage Sieve Mining Machinery , dewatering screen manufacturer

VD Vibrating Drainage Sieve Mining Machinery , dewatering screen manufacturer Mining Revolving Screen Equipment

Mining Revolving Screen Equipment CE/ISO Certified Rock Circular Vibrating Screen with High Capacity

CE/ISO Certified Rock Circular Vibrating Screen with High Capacity Popular mining circular vibrating screen, sand ore trommel screen

Popular mining circular vibrating screen, sand ore trommel screen