- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Jaw Crusher Machine>Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine

Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine

- Jaw Crusher Machine

Jaw Crusher Machine

- China

- ISO9001

- One set Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine

- [email protected]

- 1500*1500*1438mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 125

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Description

Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine

Jaw crusher machine always use to crush the various minerals or rocks with strongest anti-crush pressure less than 250 Mpa.

Jaw crusher widely used in mining industry, cement industry and concrete industry. and mainly using in first step crushing or the Middle Intermediate crusher.

| Model No. | Spec.(mm) | Weight(t) | Designing ability(t/h) | Size(mm) | Feeding Size | Outlet width | Motor Power |

| PEX150×750 | 150×750 | 4 | 8-35 | 1480×1630×1040 | 10-40mm | 15 | |

| PEX175×750 | 175×750 | 4.5 | 10-35 | 1460×1630×1170 | 15-50mm | 18.5 | |

| PEX250×750 | 250×750 | 5.824 | 15-35 | 1600×1744×1380 | 15-50mm | 30 | |

| PEX250×1000 | 250×1000 | 7.032 | 16-51 | 1600×1992×1380 | 15-50mm | 37 | |

| PEX250×1200 | 250×1200 | 9.1 | 20-60 | 1680×2200×1405 | 15-50mm | 45 | |

| PE-250 | 250×400 | 3.1 | 5-20 | 2060×1261×1413 | 20-80mm | 18.5 | |

| PE-320 | 320×500 | 4.73 | 10-38 | 1500×1500×1438 | 30-90mm | 30 | |

| PE-400 | 400×600 | 6.9 | 14-65 | 1700×1732×1596 | 40-160mm | 30 | |

| PE-400 | 400×600 | 6.5 | 17-60 | 1680×1710×1601 | ≤350mm | 40-100mm | 30 |

| PE-450 | 450×1200 | 16 | 50-100 | 2200×2360×1980 | 50-120mm | 75 | |

| PE-500 | 500×750 | 12.07 | 40-95 | 2200×1916×1970 | 50-100mm | 55 | |

| PE-600 | 600×900 | 17.67 | 60-200 | 2350×2280×2390 | 75-200mm | 75 | |

| PE750×1050 | 750×1050 | 23.42 | 80-200 | 3000×2466×2590 | 80-180mm | 90 | |

| PE750×1060 | 750×1060 | 24 | 90-260 | 3000×2466×2592 | 80-200mm | 90 | |

| PE900×1200 | 900×1200 | 52 | 140—280 | 3380×2870×3330 | 95-220mm | 110 | |

| PE1200×1500 | 1200×1500 | 101 | 400—800 | 4200×3300×3500 | 150-300mm | 200 |

Principle

Principle

| Fixed jaw vertically fixed on the front wall of the body, moving jaw is in a tilt position and forms a small crushing chamber with the fixed jaw plate by the jaw crusher machine. The movable jaw plates are periodically reciprocated against the fixed jaws, sometimes separated and sometimes close. When it is near, the material between the two jaws is crushed by crushing, bending and splitting. | |

Advatage

Advatage1) Jaw crusher machine use the world class manufacturing process, moving jaw assembly using high quality cast steel components, heavy eccentric shaft with forging processing.

2) Jaw stone crusher using the finite element analysis technique, the integral cast steel housing ensures complete cooperation with the frame, greatly enhancing the radial strength of the bearing.

3) Jaw crusher machine cavity with symmetrical "V" shaped structure and discharger with wedge adjustment device make the adjustment simpler, safer and quicker.

4) Jaw crushing equipment with larger and more durable eccentric shaft bearings and toothed panels make the equipment carrying capacity stronger. So its yield is higher, working life is Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine.

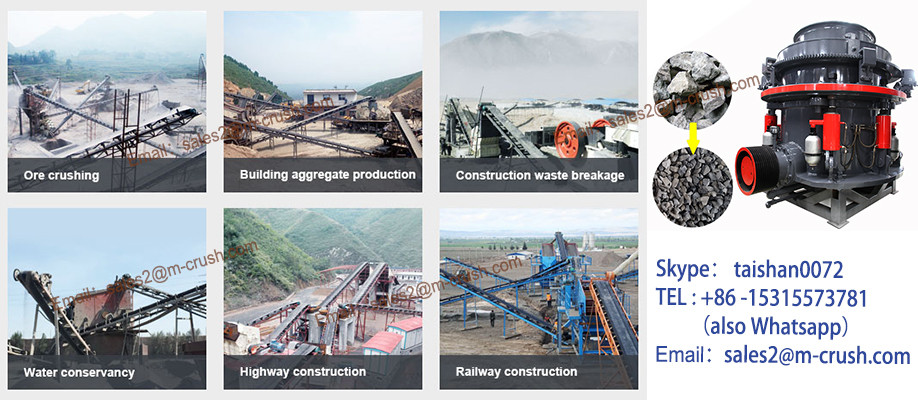

Application

Application FAQ

FAQQ1. How to maintenance the jaw crusher?

A1. In order to ensure the normal operation of the jaw crusher, in addition to correct operation, you must have plan for maintenance, including Minor repairs,Moderate maintenance,Overhaul

Q2. What is the different between the Minor repairs,Moderate maintenance and Overhaul?

A2. The repair cycle for minor repair is1-3 months, Moderate repair is 1- 2 years, the over haul cycle is 5 years per time.Q3. What is the normal protection for the jaw crusher?

A3.Closing and checking jaw crusher periodically, regularly check the driving belt of jaw crusher and lubrication of mechanical parts.

Q4. What is the temperature request when crusher working?

A4. The temperature of bearing should not exceed 30 ℃, the maximum temperature shall not exceed 70 ℃.

Q5. Things need attention when use the machine?A5. Turn off the power in time then check the reason, if the crusher stops working suddenly.

Related Products

Related Products

High Efficiency Stone Use First Step Crushing Equipment Hammer Crusher

Min. Order: 1 Set , Hammer crusher can OEM

FOB Price: US $ 3088 - 78676 / Set

Mining Equipment Stone Sand Making Vertical Shaft Crusher

Min. Order: 1 Set , Vertical shaft crusher can be OEM

FOB Price: US $ 4588 - 15440 / Set

Ore Mining Sand Making Machine Four Teeth Roller Crusher

Min. Order: 1 Set , Four Teeth Roller Crusher can be OEM

FOB Price: US $ 30290 - 138970 / Set

Large Capacity Reversible Hammer Type Stone Impact Crusher

Min. Order: 1 Set , Impact Crusher Can be OEM

FOB Price: US $ 2205 - 242647 / Set

Industry Mobile High Temperature Material Use Single Tooth Roll Crusher

Min. Order: 1 Set , Single tooth-roller crusher can be OEM

FOB Price: US $ 57647 - 176470 / Set

Min. Order: 1 Set , Cone crusher can be OEM

FOB Price: US $ 17647 - 147058 / Set

Our Company

CHAOYANG HEAVY MACHINERY MANUFACTURING CO., LTD.

was founded in 1997, with the registered capital above 13 million US Dollar. The company covers an area of about 66000 square meters, with workshops of 30000 square meters. There are 230 staffs in the company.

In 2004, the company gained ISO 9001 certification and empowered import and export right. On the other hand, the company is also the member of “ The Center of Technology Enterprise of Liaoning Province”.

Our company views product’s quality as the dynamic for developing All the main parts are wear-resistant material and manufactured by advanced technology. All machines made by us are durable and high-qualified.

Contact Us

Contact Us

Jaw Crusher Machine is fit for dry and wet sieving, classification of powdery, granular and filamentary materials and dehydration of materials. If fine sieving is required Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine can be satisfied by adopting high-efficiency screen mesh-cleaning device to improve the sieving. For wet sieving Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine is especially fit for separation of sludge (waste water) and preliminary compression of mixed matter of solid and liquid materials.

hhhghj

Jaw Crusher Machine can do according to customers special demands. We provide our customers with high-quality Jaw Crusher Machine, advanced production technology and perfect after-sales services.Using As Coarse Crushing Mining General Machinery Mini Jaw Crusher Machine Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

YHAYAG

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

New Products

Mining machinery spare parts metso jaw crusher machine C80 fixed/movable jaw plate price

Mining machinery spare parts metso jaw crusher machine C80 fixed/movable jaw plate price HD German Type White Jaw Crusher disbase dolerite crushing machine

HD German Type White Jaw Crusher disbase dolerite crushing machine Mobile crusher factory direct small gold mining machine

Mobile crusher factory direct small gold mining machine Scrap steel crusher machine/bike crusher machine/waste car recycling

Scrap steel crusher machine/bike crusher machine/waste car recycling 2018 New type jaw crusher machine price , hopper in stone crusher

2018 New type jaw crusher machine price , hopper in stone crusher