- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Fine Crusher>Heavy duty stone impact fine crusher for hot selling

Heavy duty stone impact fine crusher for hot selling

- Fine Crusher

Fine Crusher

- China

- ISO9001:2008

- One set Heavy duty stone impact fine crusher for hot selling

- [email protected]

- 2330mmx1660mmx2300mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 76

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Product Description

Product Application of Heavy duty stone impact fine crusher for hot selling

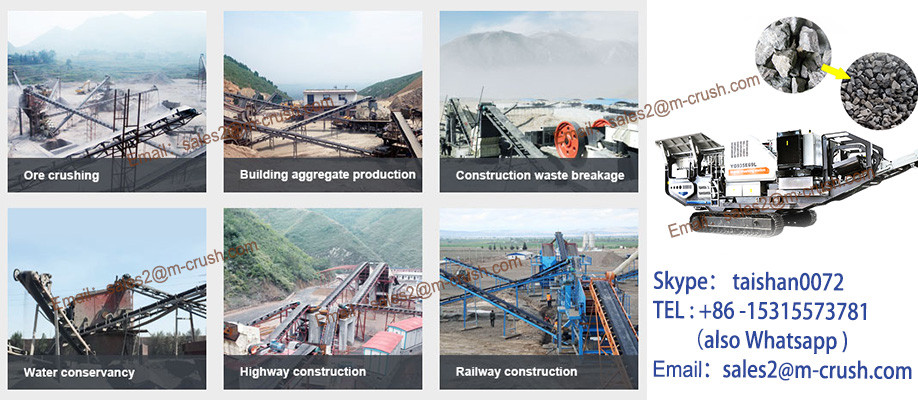

Impact crusher, which can also be called impact breaker or impact crushing machine which is used for crushing of large, medium and small materials with side length less than 500mm and compression resistance no more than 350Mpa. Heavy duty stone impact fine crusher for hot selling stone impact crusher is an optimized crushing machine after adopting advanced techniques at home and aborad and it is widely used in building material, hydroelectricity, artificial stone and sand, highway, etc.

This series of products can process the material with side length of 100 to 500mm. The compression strength can reach 350Mpa. The advantages of the products are big reduction ratio and cubic shape of the crushed materials.

| Specifications For Heavy duty stone impact fine crusher for hot selling | |||||||

| Model | Spec.(mm) | Feed opening size ( mm ) |

Feed opening size( mm ) | Capacity ( t/h) |

Power (kw ) |

Weight (t) |

Overall dimension (L×W×H) (mm) |

| PF- 1007 | Φ1000 × 700 | 400x730 | 300 | 30-70 | 37-45 | 12 | 2330x1660x2300 |

| PF- 1010 | Φ1000 × 1050 | 400 × 1080 | 350 | 50-90 | 45-55 | 15 | 2370×1700×2390 |

| PF- 1210 | Φ1250 × 1050 | 400 × 1080 | 350 | 70-130 | 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | Φ1250 × 1400 | 400 × 1430 | 350 | 100-180 | 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | Φ1320 × 1500 | 860 × 1520 | 500 | 130-250 | 200 | 27 | 3180×2720×2620 |

| PF-1520 | Φ1500× 2000 | 830 × 2040 | 700 | 300-550 | 315-400 | 50.6 | 3959×3564×3330 |

| PF-1820 | Φ1800× 2000 | 1260 ×2040 | 800 | 600-800 | 630-710 | 83.21 | 4400×3866×4009 |

Certifications

Certifications Detailed Images

Detailed Images

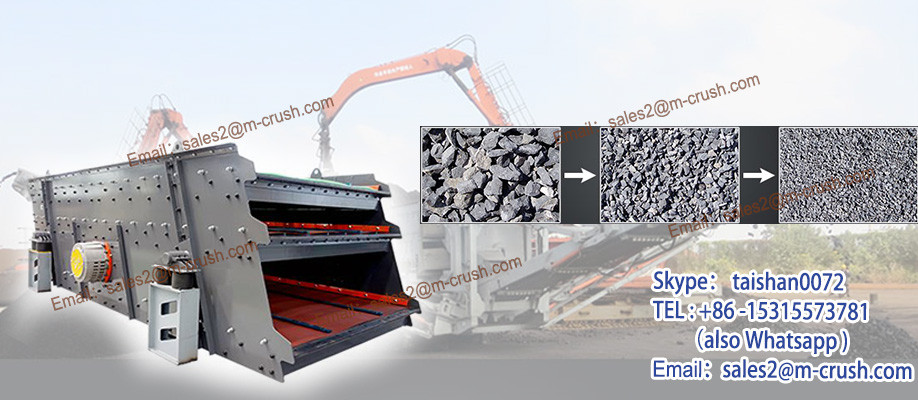

High efficiency and energy-saving

Big feeding inlet and high crushing chamber, which are applicable for large-lump hard materials with low powder rate.

Features:Big crushing ratio, high-efficiency , low energy; Special structure, no-board connection

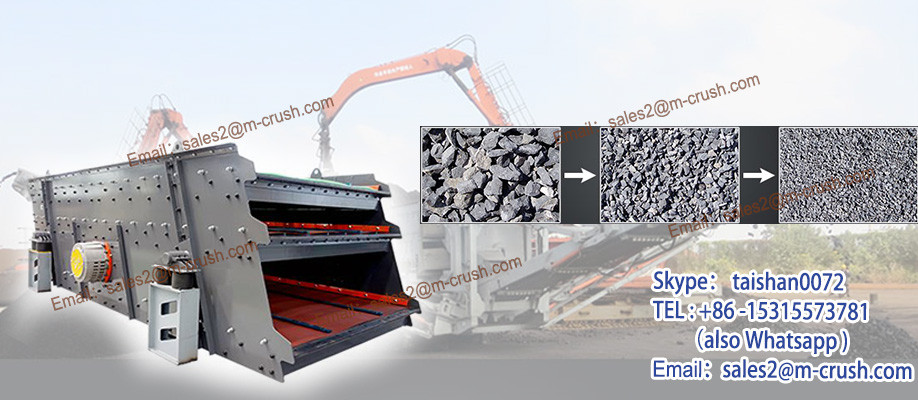

Fantastic particle-type:

The interval between impact plate and hammer can be easily adjusted, which effectively control the discharging size and ensure good particle shape.

Features: High chrome hammer, unique impact plate

Unique structure

Compact structure, strong rigidity, the rotor has a large moment of inertia.

Features: Good product size with cubical shape , no tension and crack ,simplified crushing process;

High comprehensive efficiency

High chromium hammer, resistance to wear, large impact force

Features: Convenient maintenance, reliable operation.

Application

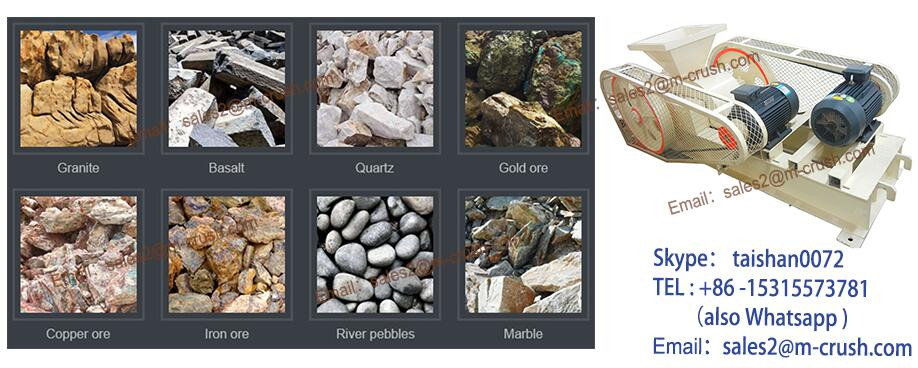

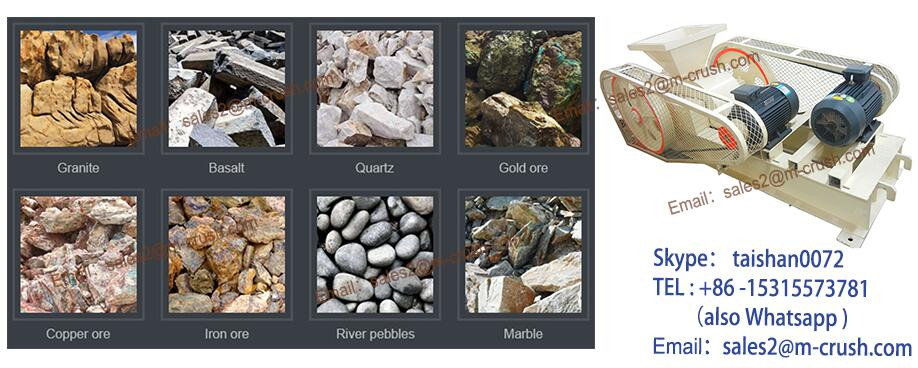

Application| Applicable material | Barite, basalt, bentonite, calcite, calcium carbonate, coal, dolomite, feldspar, granite, gravel, gypsum, micro silica, pebble, quartz, slag and so on |

| Capacity(t/h) | 50-260TPH |

| Feeding Size (mm) | |

| Model Number | PF1007, PF1010, PF1210, PF1214 ,PF1315, PF1520, PF1820 |

Heavy duty stone impact fine crusher for hot selling Impact Crusher in Ethiopia

Case Study

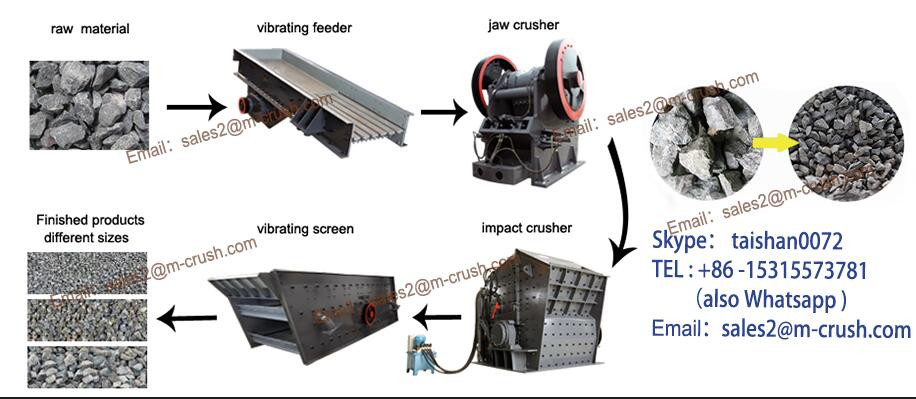

A Crushing Plant invested by Government aims to crush Granite Stones for road construction. The detailed requirements are as following:

Raw material: Granite

Feeding Size: 800mm Output size: 0-5mm, 5-20mm, 20-40mm

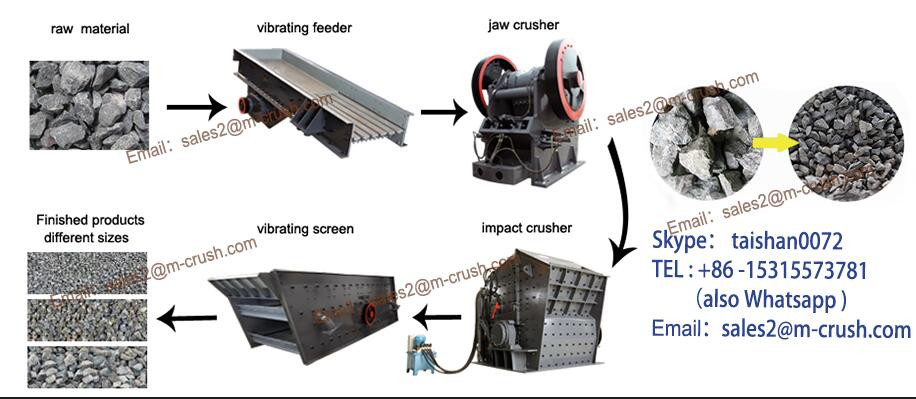

Procuction Process

The raw materials are unloaded by trucks into the hopper. By vibrating feeder, raw materials are regularly fed into Primary Jaw Crusher which could reduce 800mm stones into approx.150mm. The half-finished products from Jaw Crusher will be conveyed by Belt Conveyor to transport the material to the following Impact Crusher. After secondary crushing, products will be conveyed bt Belt Conveyor to the Vibrating Screens for size separation: 0-5mm, 5-20mm, 20-40mm and +40mm. The unrequested products which are bigger than 40mm will be returned to the tertiary TK Vertical Impact Crusher by Belt Conveyor for further crushing, while products with requested size will be piled up by Belt Conveyor . Natural fines from the grizzly bar of the vibrating feeder are conveyed by Belt Conveyor as separate stone scrap.

| Country | Uzbekistan |

| Capacity | 80T/H-100T/H |

| Material | Limestone |

| Machine list | Vibrating Feeder GZD960X3800, Jaw Crusher PE600X900, Liming hammer impact crusher price portable ore impact crusher PF1214, Vibrating Screen 3YZS1860, Blet Conveyors, and Electric Control Panel |

Minor repairs: The main contents include inspection and repair adjustment device, high-speed discharge port clearance, right turn or replace worn lining. Overhaul transmission parts, lubrication systems and replacement of lubricants. Small repair cycle is 1-3 months.

Repair: In addition to all the work carried out minor repairs, but also including the replacement of the thrust plate, liner, check and repair the bearing and so on. The repair cycle is generally about 1-2 years.

Overhaul: In addition to all the repair work, will also include replacing or turning the eccentric shaft and movable jaw mandrel, casting rod babbitt head unit, replace or repair all worn parts. Overhaul cycle is generally about 5 years.

If you want to buy accessory accessories,we provide the best quality accessories. Leave a message for us, and we'll give you the first time. Or contact me by Whatsapp: 0086 1872124 3106, I will give you feedback no more than 24 hours.

Packing & Shipping

Packing & Shipping

Packaging Detail

Packing Requirement: Standar Containers

Inner Packing: Product wrapped by PP-Bubble

Outer Packing: Load container, Spare Parts in wooden case

Storage Requirement: waterproof, put in the flat ground

Transportation

These machines are processed to be rustproof and moisture proof before delivery.

Large mainframes are in nude, while small spare parts and motors are in wooden boxes.

All items are in bulk or containers, details will be negotiated by both parts afterwards.

Jaw crusher

100% Response Rate

Hammer crusher

100% Response Rate

Mobile crushing station

100% Response Rate

Sand making machine (Sand maker)

100% Response Rate

Hydraulic cone crusher (High Automatic)

100% Response Rate

Single cylinder hydraulic cone crusher (Full automatic with PLC control system)

100% Response Rate

How to Contact Us

| Contact person | Lola Chen |

| Phone number(office) | 0086 21 50808756 |

| Mobile(Whatsapp&viber) | 0086 187 2124 3106 |

| Skype | chen.aurora1 |

| c1217198127 | |

| Website | www.sinofxm.com |

Send Message or Chat Now for Price !!!

Tips: please tell me your material and capacity to become our quality clients which will have 2%-10% discount

Please tell me your demand information, so we can send you accurate quotation:

♥ What's the raw materials you want to process(such as limestone, granite, basalt)?

♥ What is capacity you want tons per hour? such as 3-10TPH, 150TPH, 200TPH.

♥ Your email address or phone number

♥ Other requirements. (We are the Heavy duty stone impact fine crusher for hot selling manufacturer of mining machinery: jaw crusher, impact crusher, cone crusher, sand making machine, mobile crushing plant, vibrating screen etc.)

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Heavy duty stone impact fine crusher for hot selling grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Heavy duty stone impact fine crusher for hot selling coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Heavy duty stone impact fine crusher for hot selling thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Heavy duty stone impact fine crusher for hot selling adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

C100 foundry scrap gating crusher fine hydraulic concrete breaker

C100 foundry scrap gating crusher fine hydraulic concrete breaker Factory direct prices the price of vsi crusher for sale

Factory direct prices the price of vsi crusher for sale cone crusher used in large -scale stone factory

cone crusher used in large -scale stone factory Advanced technology telsmith cone crusher with good quality

Advanced technology telsmith cone crusher with good quality Size Reduction Equipment of Fine Impact Crusher

Size Reduction Equipment of Fine Impact Crusher