- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Fine Crusher>best type of small stone crusher machine high wet material fine crusher high pressure forming machine

best type of small stone crusher machine high wet material fine crusher high pressure forming machine

- Fine Crusher

Fine Crusher

- China

- One set best type of small stone crusher machine high wet material fine crusher high pressure formin

- [email protected]

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 57

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

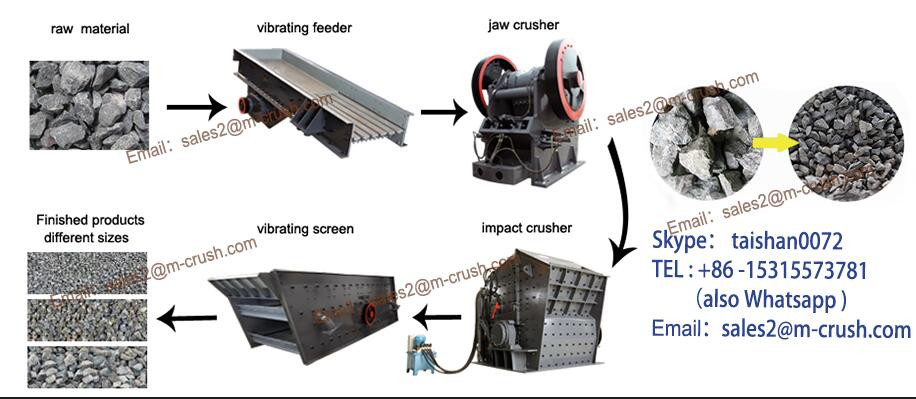

Product Description

best type of small stone crusher machine high wet material fine crusher high pressure forming machine

Enterprise introduction:

Zhengtai Machiney Factory of best type of small stone crusher machine high wet material fine crusher high pressure forming machine City is specialized in the field of full set machinery of automatic brick making machine. After 20 years' development,

our factory has a contingent of top-north researcher, an advanced manufacturing technology, perfect detection means, and a complete quality assurance system,

According to the inferior soil, coal gangue, shale, fly ash and other waste residue.

Over the years, Our factory always aim to high quality and technology development, orient to market and credibility, and gain a stable marketing system and

exported to Kazakhstan, Kyrgyzstan, India, Banglaedsh, Africa and other countries and praised by users.

The 600 High Speed Smashing roller:

Technical parameters | |

Roller standard |

800×600 |

Rotating speed of roller angle |

High speed roller 208 rpm |

Low speed roller 189 rpm | |

Linear speed of roll |

High speed roller 392 rpm |

Low speed roller 356 rpm | |

Yield |

25-40m/h |

Feed Inlet Clearance |

≤100mm |

Discharging pin-size |

2-3mm |

Motor power |

Y4-11×2 |

External dimension(length*wide size*high seize |

2200mm×1400mm×1450mm |

Our Machine represent:

Through decades of application and practice in crushing industry, as well as the improvement of serialization manufacture and technical level,

the two-stage crusher designed by “Zhengtai Machinery” presents incomparable superiority.

Utilized in fuel workshop of thermal power plant, the machine can replaces jaw breaker, ring-hammer crusher and fine grinder etc. It features

low investment, small occupied space, few operating personnel, economic and effective operation, its effects of energy consumption reduction

are notable.

It is used in the fine crushing before the raw materials entering into the grinder in mines and cement plants, the basic principle of “more crushing,

less grinding” is reflected, function of fine crushing is brought into fully playing to enhance the processing capacity grinders, electricity consumption

and steel ball consumption are reduced, volume of production of grinders is greatly increased.

Used in the brick making enterprise that are using coal gangue and shale to produce new type wall materials, the problem of raw materials with high

moisture troubling normal production of brickyard is solved, the particle grading is reasonable, particularly suitable for production of perforated brick

and thin brick.

The crusher is equivalent to two sets of hammer crusher and combined into a whole one reasonably, cascaded using of two sets of rotor without screen,

has the following characteristics:

1. Dual Rotor Crushing in Up and Down Two-stage

Two sets of cascade rotors make the materials crushed by up stage rotor hammer be fine crushed by the rotary down rotor hammer, materials in the inner

space collide with each other reversely and smash one another, the effect of hammer crushes materials crush materials is achieved, and they can be unloaded

directly.

2. No Screen, No Blocking for Materials with High Moisture Content

The traditional crushers with grate sieve plate can not meet the raw materials with the moisture content higher than 8%, serious blocking will occur if the moisture

content of raw materials is higher than 10%, and the hammer can not rotate and materials can not be discharged, even the motor will be burned out and effect the

production.

The design of the crusher is without screen, it has no strict requirements on moisture content of raw materials, the problem of blocking on the sieve plate is absent,

and troubles that fine powers can not be discharged in time and repeated grinding do not exist either, so the grinding efficiency is high, and invalid abrasion of hammer

does not exist.

3.Unique Bidirectional Gap Adjustment Technology

Granularity will coarsen and the gap between abraded hammer and liner plate largens after the hammer consuming, it is proper to move the position of hammer from the

center to the outside to reduce the gap with liner plate and to continue to use. It is also allowable to push the liner plate outside-in to regulate the gap and control the granularity

of discharged materials.

4. Equipped with Balance Wheel Giving Steady Rotation and High inertia, Saving Electricity for 20%

Ends of two sets of rotor spindle up and down are equipped with flywheels, which can regulate the periodical speed fluctuation of operation, and make operation uniform

and steady, increase rotational inertia and overcome resistance to motion, ia can save the electricity for more than 20%.

5. Centralized Lubrication System, Oiling without Machine Halt, Conveniently and Efficiently.

Lubrication system of two-stage crusher changes the traditional lubricating oil injection method of grease cup; the centralized oil feeding equipped proportioning pump has

one step of operation and can supply oil for multi-way; the complete machine can injects lubrication oil synchronouslyto all bearings under working position, which is

convenient and efficient, it can also prevent intrusion of dust damaging the bearings.

6.Hydraulic Pressure Starting Case

Hydraulic pressure starting and stopping equipment needs one person to start and stop the case easily. It is not only light and handy, but also safe, reliable, and convenient

for repairing.

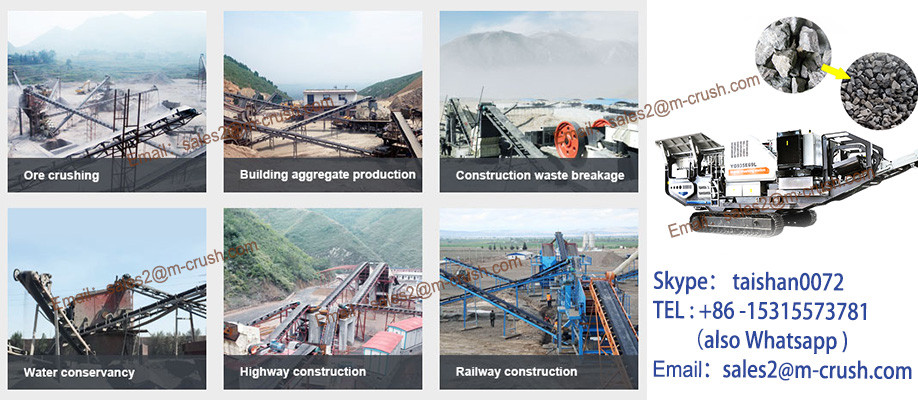

Clients visit our factory:

Our machine are deliverying:

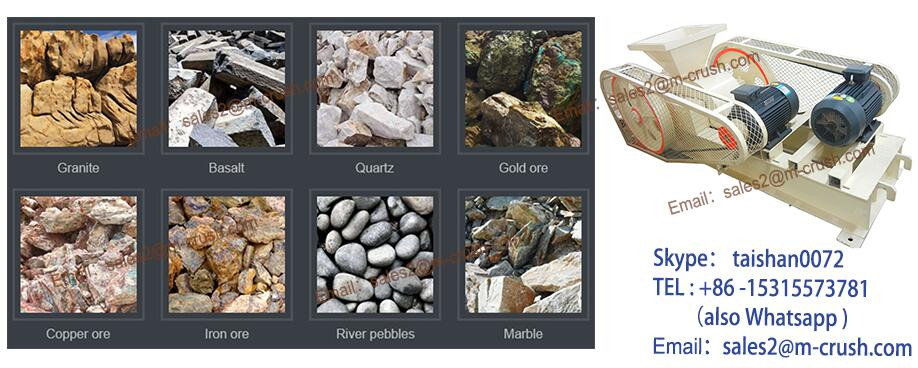

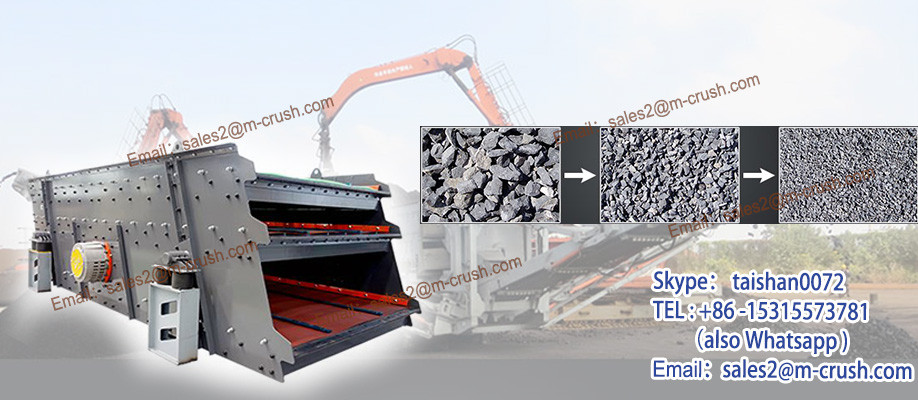

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.best type of small stone crusher machine high wet material fine crusher high pressure forming machine grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,best type of small stone crusher machine high wet material fine crusher high pressure forming machine coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and best type of small stone crusher machine high wet material fine crusher high pressure forming machine thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.best type of small stone crusher machine high wet material fine crusher high pressure forming machine adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

C100 foundry scrap gating crusher fine hydraulic concrete breaker

C100 foundry scrap gating crusher fine hydraulic concrete breaker Factory direct prices the price of vsi crusher for sale

Factory direct prices the price of vsi crusher for sale cone crusher used in large -scale stone factory

cone crusher used in large -scale stone factory Advanced technology telsmith cone crusher with good quality

Advanced technology telsmith cone crusher with good quality Size Reduction Equipment of Fine Impact Crusher

Size Reduction Equipment of Fine Impact Crusher