- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Fine Crusher>Stone Crushing Screening Plants impact crusher

Stone Crushing Screening Plants impact crusher

- Fine Crusher

Fine Crusher

- China

- ISO&CE

- One set Stone Crushing Screening Plants impact crusher

- [email protected]

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 162

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Impact Fine Crusher is used for fine crushing or all kinds of ore granuls

Highly Effective Impact Fine Crusher

Impact Crusher is our improved product of crusher. Its biggest advantage is as follows: the product is of cubic shape without crack. The machine is of reasonable structure, wide use, high efficiency, simple operation and maintenance and excellent safe performance.

PCX highly effective impact fine crusher (the third generation sand making machine) is a new type sand making equipment developed by combining the domestic and overseas technology with the working conditions of related industries.

Impact fine crusher is used for fine crushing medium hard materials in concrete industry, such as limestone, plaster, clinker, mixed material, calcium phosphide, dolomite, and pearl ore, etc.

Impact Fine crusher is also applicable to building material, fertilizer, mine and fireproofing material industries.

Features of Highly Effective Impact Fine Crusher:

Highly effective impact fine crusher is a kind of efficient and energy-saving crushing machine.

Esong Impact Fine crusher has the characteristics of simple structure, stable performance, high productivity, low energy consumption, and easy maintenance, etc.

The discharging materials are of small and equal size Our Impact Fine crusher hammer has long service life.

By using our efficient highly effective impact fine crusher, tertiary crushing can be changed to secondary crushing.

Technical Parameters:

A. Model: PCX 800×400

1.Size of feeding hole (mm): 400×185

2.Max. feeding Size (mm): 120

3.Discharging size (mm): Discharging size (mm)

4.Discharging Width Control (mm): Discharging Width Control (mm)

5.Productivity(t/h) of Cement Clinker: 20-30

6.Productivity(t/h) of imestone: 30-45

7.Productivity(t/h) of Glass sand: 35-45

8.Power(kw): 22-37

B. Model: PCX 800×600

1.Size of feeding hole (mm): 500×250

2.Max. feeding Size (mm): 180

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 35-40

6.Productivity(t/h) of imestone: 40-55

7.Productivity(t/h) of Glass sand: 45-55

8.Power(kw): 37-45

C. Model: PCX 800×800

1.Size of feeding hole (mm): 550×330

2.Max. feeding Size (mm): 180

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 35-45

6.Productivity(t/h) of imestone: 60-65

7.Productivity(t/h) of Glass sand: 55-65

8.Power(kw): 37-45

D. Model: PCX 1010×1010

1.Size of feeding hole (mm): 1000×350

2.Max. feeding Size (mm): 180

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 45-55

6.Productivity(t/h) of imestone: 60-75

7.Productivity(t/h) of Glass sand: 65-75

8.Power(kw): 45-55

E. Model: PCX 1200×1000

1.Size of feeding hole (mm): 1200×400

2.Max. feeding Size (mm): 180

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 80-110

6.Productivity(t/h) of imestone: 80-100

7.Productivity(t/h) of Glass sand: 80-100

8.Power(kw): 90-110

F. Model: PCX 1200×1200

1.Size of feeding hole (mm): 1200×450

2.Max. feeding Size (mm): 180

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 100-110

6.Productivity(t/h) of imestone: 90-100

7.Productivity(t/h) of Glass sand: 90-120

8.Power(kw): 110-132

G. Model: PCX 1400×1400

1.Size of feeding hole (mm): 1500×500

2.Max. feeding Size (mm): 190

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 100-150

6.Productivity(t/h) of imestone: 100-150

7.Productivity(t/h) of Glass sand: 120-150

8.Power(kw): 160

H. Model: PCX 1600×1600

1.Size of feeding hole (mm): 1600×550

2.Max. feeding Size (mm): 190

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 170-210

6.Productivity(t/h) of imestone: 190-250

7.Productivity(t/h) of Glass sand: 190-250

8.Power(kw): 250

I. Model: PCX 1800×1800

1.Size of feeding hole (mm): 1800×800

2.Max. feeding Size (mm): 190

3.Discharging size (mm): Discharging size (mm): ≤5

4.Discharging Width Control (mm): Discharging Width Control (mm): 5-20

5.Productivity(t/h) of Cement Clinker: 250-270

6.Productivity(t/h) of imestone: 280-310

7.Productivity(t/h) of Glass sand: 280-310

8.Power(kw): 280

Main technical parameters:

PCX800×300 |

≤60 |

≤5(96%) |

20-25 |

37 |

2.5 |

PCX800×600 |

≤60 |

≤5(94%) |

35-50 |

45 |

4.7 |

PCX800×800 |

≤70 |

≤5(92%) |

40-60 |

75 |

6.5 |

PCX1000×1000 |

≤80 |

≤5(91%) |

60-90 |

90 |

8.8 |

PCX1000×1200 |

≤90 |

≤5(88%) |

75-110 |

110 |

13.6 |

PCX1300×1200 |

≤100 |

≤5(86%) |

120-145 |

160 |

19.5 |

PCX1300×1400 |

≤120 |

≤5(85%) |

145-180 |

180 |

26 |

...

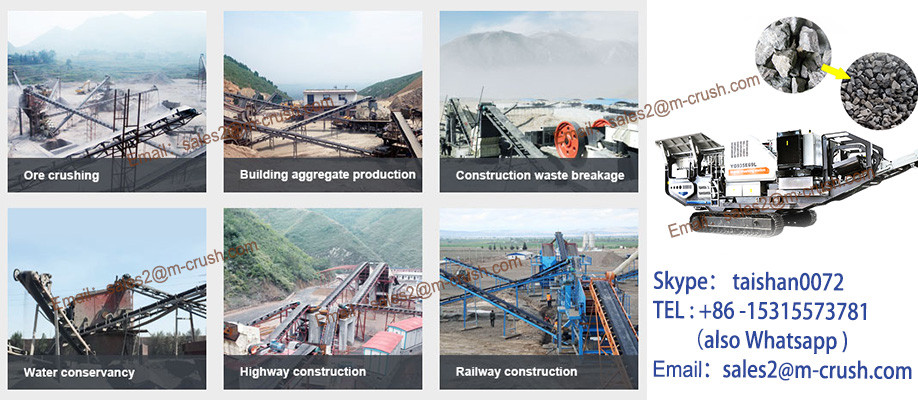

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Stone Crushing Screening Plants impact crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Stone Crushing Screening Plants impact crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Stone Crushing Screening Plants impact crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Stone Crushing Screening Plants impact crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

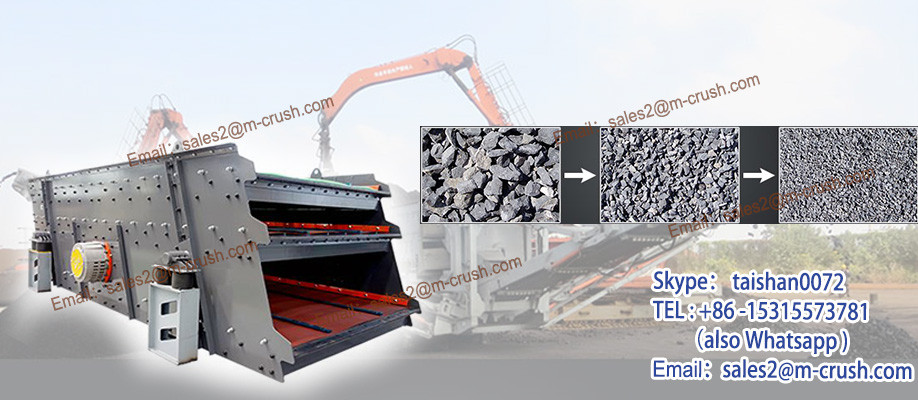

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

C100 foundry scrap gating crusher fine hydraulic concrete breaker

C100 foundry scrap gating crusher fine hydraulic concrete breaker Factory direct prices the price of vsi crusher for sale

Factory direct prices the price of vsi crusher for sale cone crusher used in large -scale stone factory

cone crusher used in large -scale stone factory Advanced technology telsmith cone crusher with good quality

Advanced technology telsmith cone crusher with good quality Size Reduction Equipment of Fine Impact Crusher

Size Reduction Equipment of Fine Impact Crusher