- Shandong Brawny Industrial Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Fine Crusher>Iron Ore Crushing Plant Double Roller Teethed Crusher

Iron Ore Crushing Plant Double Roller Teethed Crusher

- Fine Crusher

Fine Crusher

- China

- ISO9001:2008

- One set Iron Ore Crushing Plant Double Roller Teethed Crusher

- [email protected]

- 1150x1275x1240mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 78

-

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Brawny Industrial Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Overview

This kind of Roller Crusher is designed based on the concept American Gangrak Crusher which is our new developed product for crushing kinds of chemical cement, refractories, electricity, building material and mineral processing.

Principle

The two rollers have wedge or gasket adjusting device, wedge device with the top adjustment bolt, when the adjustment bolt wedge block upward pull up, wedge will activities roller top from fixed wheel, two roller gap becomes larger, the discharge size becomes larger, when the wedge block down, activity roller compression spring (or pressing oil cylinder) under the action of two gap becomes smaller, the discharge size becomes smaller. Gasket device is through increase or decrease the number of gasket thickness to adjust the size of the discharge size, when adding gasket will make two roller wheel gap bigger, when reduce gasket will make two roller wheel clearance decrescent, the discharge size becomes smaller .

Features

1) High crushing capacity, safe and reliable

2) Roller spacing hydraulic adjustment, roller bearing lubrication

3) tooth profile optimization design, tensile shear selective crushing, discharge material evenly

4) convenient repair, overload protection, sensitive, safe and reliable.

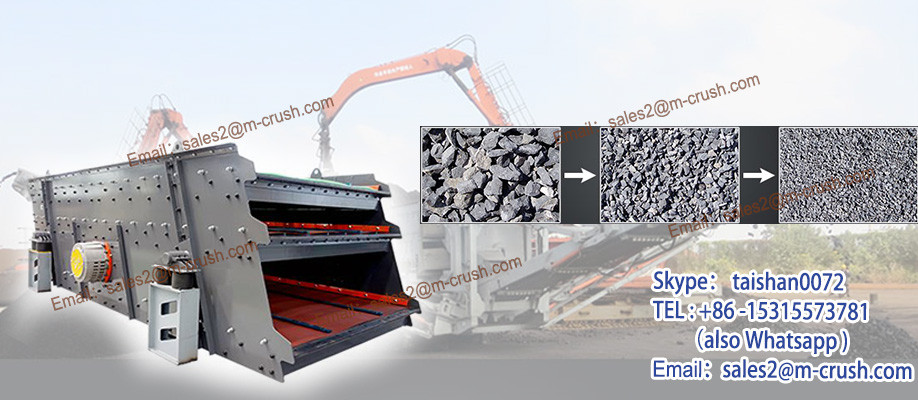

Technical Data

Model |

Roller size (mm) |

Max feed size (mm) |

Discharge size(mm) |

Capacity (t/h) |

Speed (r/min) |

Power (kw) |

Weight (t) |

remark |

2PGC0405 |

450×500 |

200 |

0-50 |

20-55 |

64 |

2×5.5 |

3.4 |

|

2PGC0607 |

600×750 |

300 |

0-50 |

60-125 |

64 |

2×11 |

7.23 |

|

2PGC0909 |

900×900 |

300 |

0-50 |

125-180 |

65.5 |

2×30 |

13.8 |

|

2PGC0912 |

900×1200 |

300 |

0-50 |

130-200 |

65.54 |

2×45 |

18 |

|

2PGCY1212 |

1260×1220 |

500 |

0-100 |

150-250 |

110 |

2×75 |

30 |

Hydraulic |

2PGC1215 |

1260×1500 |

500 |

0-100 |

180-300 |

110 |

2×90 |

36.6 |

Hydraulic |

2PGC1414 |

1400×1400 |

600 |

0-100 |

200-400 |

125 |

2×110 |

44 |

Hydraulic |

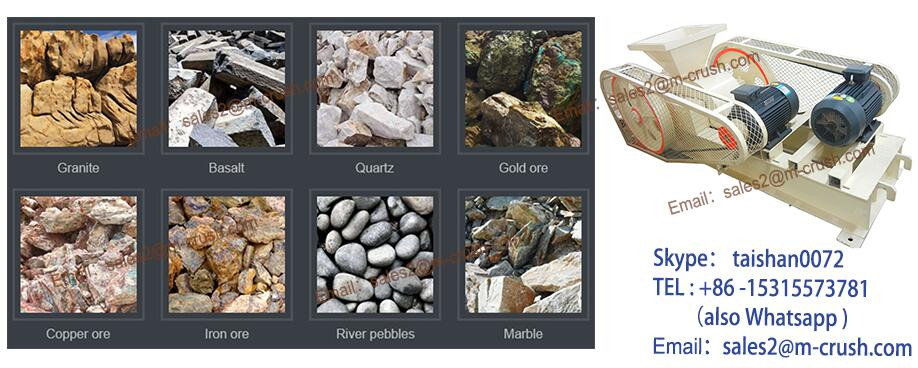

Stone Gallery

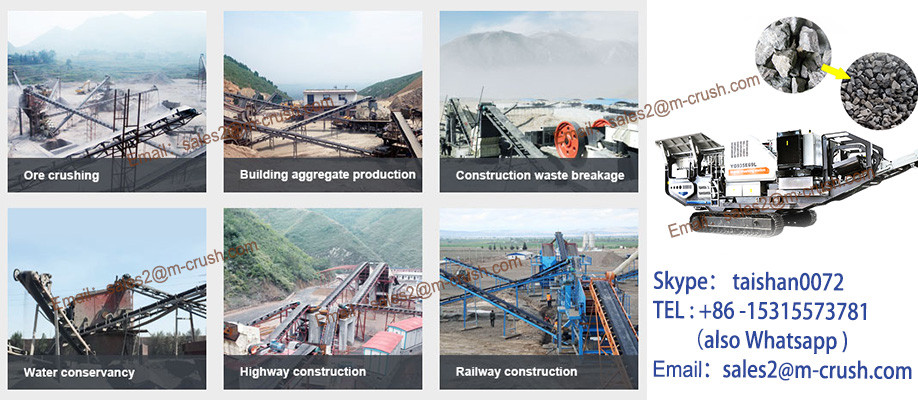

Customer visits

Factory show

Dewo Service

Our service

Dewo can provide turkey service for customers, such as engineering consultation, engineering design, equipment manufacturing, packing & transportation, installation & commissioning personnel training etc.

About Spare Parts

Dewo Machinery will be dedicated to provide our customers with genuine spare parts with high quality. With our technological advice, the life cycle of your machine can be prolonged and sustained significantly with high effectiveness.

About Training

Dewo machinery could offer excellent facilities and comfortable environment and training services to different customers. The training should include product training, safety training, operation training, maintenance know-how, technical know-how training, and regulations training, etc. All of the training is customized to fulfill every customer’s expectations. Training programs can be conducted in our workshop, or at customer’s site.

About Installation and Commissioning

Dewo are able to guide the overall installation of whole set production line, including crushing production line and cement equipment production line, etc., which will allow you to start the normal operation of equipment immediately. After installation,we will make inspection of the whole machine commissioning and operation condition and provide you testing data report of installation.

FAQ

Q: For providing you the suitable quotation we need to know the following information:

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product? Once we get your answers, I can provide you the best quotation immediately.

Remarks: The price will depend on different models. Reply message you will get 5% discount price.

Q: What about Warranty of the products?

A: Dewo Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q: The reason you choose Dewo Machinery:

A: 1. Professional manufacturer of supplying mining crushing equipment, construction equipment, Ore beneficiation equipment and mining dryers.

2. Experienced and professional R&D team and manufacturing team;

3. Professional sales team consisted of dedicated, dynamic and innovative people with international version.

4. Professional logistics service ensuring safety and timely delivery of products all over the world through Iron Ore Crushing Plant Double Roller Teethed Crusher, airline, road and railway.

CONTACT US

Welcome to visit our company and log in our website: http:www.dewomachinery.comand for more information.

If you are interesting in our products, please contact me at any time.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Iron Ore Crushing Plant Double Roller Teethed Crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Iron Ore Crushing Plant Double Roller Teethed Crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Iron Ore Crushing Plant Double Roller Teethed Crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Iron Ore Crushing Plant Double Roller Teethed Crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK

Contact Us

- Shandong Brawny Industrial Co.,Ltd

- Phone(Working Time)

Product Categories

- Jaw Crusher Machine

- Cone Crusher Machine

- Sand Washing Machine

- Fine Crusher

- Cone Crusher Machine

- Impact Rock Crusher

- Single Cylinder Hydraulic Cone Crusher

- Gravity Roller Conveyor

- Spring Cone Crusher

- Circular Vibrating Screen

- Mineral Processing Equipment

- Mining Vibrating Screen

- Jaw Crusher Machine

- Sand Making Machine

- Hammer Mill Crusher

- Vibrating Screen Feeder

C100 foundry scrap gating crusher fine hydraulic concrete breaker

C100 foundry scrap gating crusher fine hydraulic concrete breaker Factory direct prices the price of vsi crusher for sale

Factory direct prices the price of vsi crusher for sale cone crusher used in large -scale stone factory

cone crusher used in large -scale stone factory Advanced technology telsmith cone crusher with good quality

Advanced technology telsmith cone crusher with good quality Size Reduction Equipment of Fine Impact Crusher

Size Reduction Equipment of Fine Impact Crusher